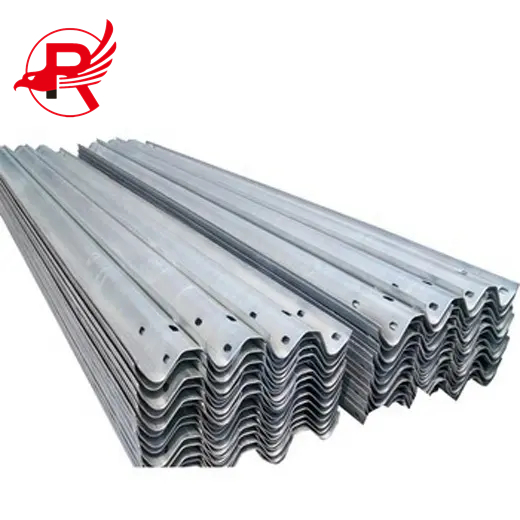

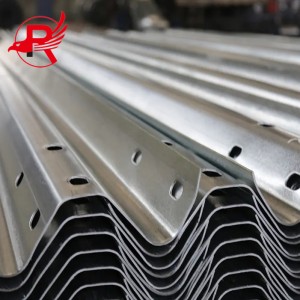

Гарачае ацынкаванае агароджванне з металічнай бэлькі Q235 з ацынкаванай сталі

| Імя | Агароджа W-бэлькі паводле AASHTO M180 |

| Памер | Эфектыўная даўжыня секцыі бэлькі 12,5 футаў або 25,0 футаў Можна наладзіць |

| Таўшчыня сталі | Клас А = 2,67 мм (0,105 цалі) Клас B = 3,43 мм (0,135 цалі) Можна наладзіць. |

| Апрацоўка паверхні | Гарачае ацынкаванне ў адпаведнасці з ASTM A653 |

| Таўшчыня цынкавага пакрыцця | Тып 1 = Ацынкаванае пакрыццё 550 г/кв. м мінімум адна пляма Тып 2 = Ацынкаванае пакрыццё 1100 г/кв. м мінімум адна пляма Тып 3 = сталь без пакрыцця Тып 4 = сталь, устойлівая да атмасферных уздзеянняў Можна наладзіць. |

| Бясплатны ўзор | Даступна |

| Час вытворчасці: | Прыкладна 7~15 рабочых дзён. |

| Вытворчая магутнасць | 60000 тон/месяц |

| Гарантыя | 2 гады |

металічная перагародкамаюць шырокі спектр прымянення, у тым ліку:

1. Бяспека: Металічныя бар'еры могуць выкарыстоўвацца для фізічнай абароны маёмасці або прадухілення несанкцыянаванага доступу ў забароненыя зоны. Яны звычайна выкарыстоўваюцца ў аб'ектах з высокай ступенню бяспекі, такіх як аэрапорты, урадавыя будынкі і ваенныя аб'екты.

2. Кіраванне транспартным сродкам:металічная агароджа з бар'ерамТакія як слупкі, агароджы і вароты, могуць выкарыстоўвацца для рэгулявання руху транспартных сродкаў і прадухілення аварый. Яны звычайна выкарыстоўваюцца на паркоўках, пунктах спагнання платы за праезд і будаўнічых пляцоўках.

Заўвага:

1. Бясплатны адбор проб, 100% гарантыя якасці пасля продажу, падтрымка любога спосабу аплаты;

2. Усе астатнія спецыфікацыі круглых труб з вугляродзістай сталі даступныя ў адпаведнасці з вашымі патрабаваннямі (OEM і ODM)! Завадскую цану вы атрымаеце ад ROYAL GROUP.

Працэссталёвы дарожны бар'ерўключае ў сябе некалькі этапаў. Вось агульны агляд працэсу:

1. Праектаванне: Першым крокам у вытворчасці металічных агароджаў з'яўляецца іх праектаванне. Праекціроўшчыкі выкарыстоўваюць праграмнае забеспячэнне для аўтаматызаванага праектавання (САПР) для стварэння праектаў.

2. Выбар матэрыялу: Пасля завяршэння праектавання наступным крокам з'яўляецца выбар адпаведнага матэрыялу для перашкоды. Да распаўсюджаных матэрыялаў адносяцца сталь, алюміній і жалеза.

3. Рэзка: Пасля выбару матэрыялаў наступным крокам з'яўляецца іх нарэзка па патрэбным памеры і форме. Гэта можна зрабіць з дапамогай розных рэжучых інструментаў, такіх як гідраабразіўныя, лазерныя і плазменныя разцы.

4. Фармаванне: Пасля таго, як матэрыял разрэзаны, яму надаюць патрэбную форму і памер з дапамогай розных працэсаў, такіх як гнутка, пракатка і штампоўка.

5. Зварка: Пасля таго, як дэталі сфарміраваны, іх зварваюць разам, каб утварыць гатовы бар'ер. Зварка выконваецца з выкарыстаннем розных метадаў, у тым ліку дугавой зваркі і газавай зваркі.

6. Аздабленне: Пасля зваркі перашкода праходзіць працэс аздаблення. Гэта можа ўключаць пяскоструйную апрацоўку, парашковае пакрыццё або афарбоўку для абароны металу ад непагадзі і надання яму дэкаратыўнай паверхні.

7. Кантроль якасці: Перад адпраўкай металічныя агароджы праходзяць працэс кантролю якасці, каб пераканацца, што яны адпавядаюць неабходным стандартам і не маюць дэфектаў.

У цэлым, працэс вырабу металічнай агароджы - гэта складаны працэс, які ўключае ў сябе мноства розных этапаў і патрабуе кваліфікаваных рабочых са спецыяльнымі ведамі і абсталяваннем.

Упакоўка звычайна голая, абвязка са сталёвага дроту, вельмі трывалая.

Калі ў вас ёсць асаблівыя патрабаванні, вы можаце выкарыстоўваць упакоўку, устойлівую да іржы, і больш прыгожую.

Транспарт:Экспрэс (дастаўка ўзораў), авіяцыйныя, чыгуначныя, наземныя, марскія перавозкі (FCL, LCL або насыпныя перавозкі)

Забаўляльны кліент

Мы прымаем кітайскіх агентаў ад кліентаў з усяго свету, каб наведаць нашу кампанію, і кожны кліент поўны ўпэўненасці і даверу да нашага прадпрыемства.

Пытанне: Ці з'яўляецца вытворцам UA?

A: Так, мы з'яўляемся вытворцам. У нас ёсць уласная фабрыка, размешчаная ў горадзе Цяньцзінь, Кітай.

Пытанне: Ці магу я атрымаць пробны заказ толькі на некалькі тон?

A: Вядома. Мы можам адправіць вам груз з дапамогай паслугі LCL (меншая колькасць кантэйнераў).

Пытанне: Калі ўзор бясплатны?

A: Узор бясплатны, але пакупнік аплачвае дастаўку.

Пытанне: Вы пастаўшчык золата і робіце гарантыю гандлю?

A: Мы з'яўляемся пастаўшчыком золата на сем гадоў і прымаем гарантыю гандлю.